Thunderbolt: Difference between revisions

No edit summary |

No edit summary |

||

| Line 6: | Line 6: | ||

|phase=1 or 3 | |phase=1 or 3 | ||

|voltage=120, 220, 240, or 480 | |voltage=120, 220, 240, or 480 | ||

|output= | |output=125-130 | ||

|succeeded=[[2001SRN]] | |succeeded=[[2001SRN]] | ||

}} | }} | ||

Revision as of 06:31, 8 June 2017

| Thunderbolt | |

[[File: |200px]] |200px]]

| |

| Company | Federal Signal Corporation |

|---|---|

| Produced | 1952-1993 |

| Type | Electromechanical |

| Sound output | 125-130 |

| Voltage | 120, 220, 240, or 480 V |

| Succeeded by | 2001SRN |

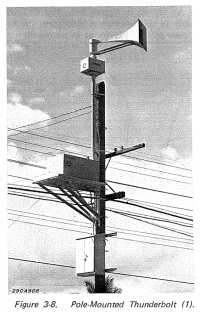

The Thunderbolt siren was a supercharged electromechanical siren produced by Federal Enterprises, which later became known as Federal Sign & Signal, and finally Federal Signal. The Thunderbolt has seven chopper levels, or voltage settings, that allow the pitch to be adjusted on the chopper, which gave the benefit to use lower or higher tones depending on the terrain and surroundings. The Thunderbolt can come in three port ratios, 5 Port single tone, or 4/5, and 5/6 Port dual tone. This siren was invented in the late 40s/early 50s as a cold war siren to warn the public of an air raid attack, later to be reissued as a multi-purpose disaster siren for weather, chemical spills, fires, or anything else that may deem appropriate. This siren went through many changes throughout it's life, and made quite a reputation as one of the best sirens in the market.

Thunderbolt 1000

The Thunderbolt 1000 is a single-tone siren. The 1000's chopper has 5 ports. This model was the first and last of the Thunderbolt, being the only model from 1952-1959, optional from 1960-1992, then the one and only model in 1993.

Thunderbolt 1000T

The Thunderbolt 1000T is a dual-toned siren. The 1000T came in 4/5 or 5/6 port ratios, which correspond to minor 3rd and major 3rd intervals, respectively.

Thunderbolt 1003

The Thunderbolt 1003 uses two solenoids that are attached to the throat of the horn. Each solenoid has a gate that closes off one row of ports on the stator. They are used to create alternating steady, alternating wail, pulsed steady, and pulsed wail signals, which can be used as a fire warning. Otherwise, it is identical to the 1000T, but used the 5/6 rotor only. Although the 4/5 port rotor is compatible, it was never offered originally.

Other models

Thunderbolt 2000

The Thunderbolt 2000 is a variant from the 1950s with a gas-powered blower. This model was single-tone only.

System 7000

The System 7000, a variant of the original Thunderbolt versions, is equipped with a self-contained generator. This particular series came in three versions; the 7012, corresponding to the 1000. the 7022, corresponding to the 1000T, and the 7026, corresponding to the 1003.

Other Information

Rotators

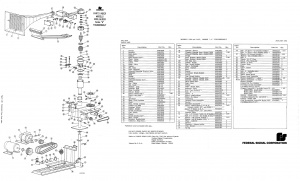

Originally the Thunderbolt used a motor and an Abart gear reducer driven by pulley to drive the large spur gear which makes the projector rotate. The pulleys utilized 3 different belt slots to change the RPM in which the siren rotates, from 2, 4, and 8 RPM. In the 80s Federal wanted to make the Thunderbolt more maintenance free, doing so by turning the motor and gear reducer to face each other and attached to make a direct drive system which rotated at 4 RPM. This rotator was used only on the B-series models. Later at the end of the Thunderbolt's life, Federal tried one more time to make the Thunderbolt better by designing a system that was truly direct drive. This model was rid of the problematic gear reducer and belts and managed to make a low power slow turning system that spins at 3 RPM. The motor was turned vertically with the shaft facing upwards with a gear attached to drive the spur gear directly. The design was efficient and really compact. This rotator was only featured on the last Thunderbolt model in 1993, and made it's appearance again on the 2001-SRNB, now used on the latest 2001-130, Equinox, and 508 sirens from Federal.

Blowers

All Thunderbolts run on what is known as a "blower" to push air to the top of the siren to increase sound output. The type of blower has changed during production; starting in 1952, thunderbolts used a 6M, then switched to the 5M blower around 1960, later to the 4M in the late 1960s. This was used up until 1980, when thunderbolts started to have the 4M roots blower mounted vertically, which was used all the way up to the end of its production in 1993. The units consisted of a motor and a Sutorbilt roots blower unit that was driven by belt pulleys attached to the blower and motor. The blower then took in air and pushed it into the pipes. They also had a "relief valve" that was mounted right outside of the roots blower, this acted as a "jam protection" system that would open if something was stuck in the standpipe. If something was stuck inside, air pressure would build up and would lift the relief valve open and let the air escape before the blower either, perforated the standpipe, blew off the chopper in the siren, or possibly cause the blower to literally explode.

Projectors

A notable feature of some Thunderbolts is their projector, or "horn". The earliest thunderbolts had metal cross support bars, now referred to as "Jailbars", throughout the horn making a 3x3 grid in the front, 2x2 in the middle, and 2x2 in the back. This acted like reinforcements. Since the Thunderbolt was new at the time, Federal wanted to make sure the horn did not warp or bend as this would ruin the sound output. After 1952, Federal started testing to see if there really was any benefit from having these "supports" in the projector, this caused some models to have them, and some to lack them. After 1955, it became obvious that the thick metal panels used for the projector were strong enough to not compromise the projector itself. Federal decided to drop the reinforced projectors and continue making the models with nothing more than a mesh screen used to keep various animals, insects, and debris out so the rotor wouldn't lock up leading to a burnt motor.