Southern California Edison Model 120

| Southern California Edison Model 120 | |

[[File: |200px]] |200px]]

| |

| Company | Southern California Edison |

|---|---|

| Produced | September 1982 |

| Type | Pneumatic |

| Sound output | 120 |

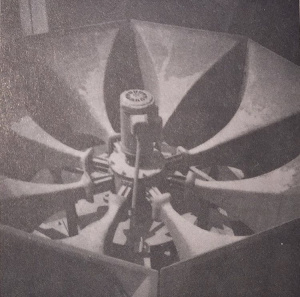

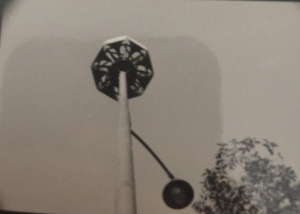

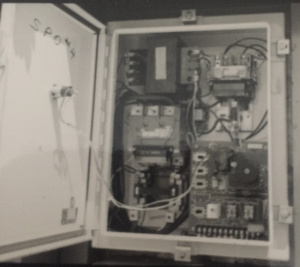

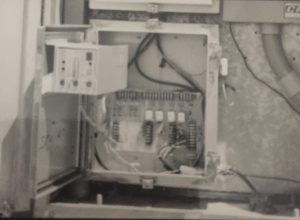

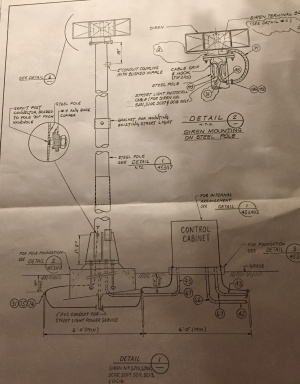

The Socal Edison (SCE) 120 or Model 120 was a SoCal Edison manufactured 120 dB siren which was designed by John Glenn Powell. He is a now retired sound engineer at the San Onofre Nuclear Generating Station located in San Clemente, California. There were 22 of these sirens produced with one being never installed which is now privately owned. 21 were installed in September 1982 to add into a system of 29 Federal Signal STL-10s that were installed in October 1981. The reason these sirens were made is because there was no other siren available that would meet the plants needs. They did look into Cyclone 120s but they realized that they have massive 50 Hp motors and are 3 Phase (which the plant wanted to use 1 phase motors.) the other reason is because the STL-10s underperformed in all areas they were placed in ,as well as federal lied to them about the STL-10 being 120 decibels and carry 6,000+ feet. So starting in late 1981 ,Model 120 prototypes started to be made and tested with the final designed units being completed and installed in September of 1982. Originally the plan was to have all 50 sirens Model 120s Which means swapping out the existing 29 STL-10s with 120s ,but the plant decided just to keep the underperforming STL-10s and just add 21 Model 120s in areas that need more coverage. For around a decade, they were thought to be "Toshiba" sirens, because they were pneumatic and people just assumed they were made by Toshiba, who also made pneumatic sirens. The Model 120 is a Pneumatic siren, meaning it requires an external air source to produce sound. The sound is chopped by a rotor, which sits inside a hollow cylinder, or stator, which acts as a chamber to contain the air inside. 8 Small narrow slots on the stator allow the sound to come out. The sound is then projected by 8 large fiberglass horns. It consists of a belt driven Paxton blower, that uses a 5 Hp TEFC motor. The rotor is 9.75 inches in diameter and has 5 ports. Including the stator it is in total 11.75 inches in diameter. The rotor is powered by a 2 Hp TEFC motor that spins at 3600 RPM. After about 10-15 years of being exposed to salty air ,the Model 120s were starting to develop corrosion on their rotor and blower motors due to the motors being residential use motors instead of commercial use motors. Also ,they did not have corrosion resistant paint like ,motors on commercially produced sirens ,This lead to SONGS having some malfunctions as well as them sometimes failing to sound on routine maintenance and tests. Starting In November 2005 ,the Model 120s and the STL-10s were starting to be gradually removed and replaced ,and by Febuary 2006 all have been replaced. Whelen WPS 2810s and WPS 2806s were installed in their places. The 2810s are in place of the Model 120s and the 2806s are in place of the STL-10s. These new electronic sirens have battery backup, and are more efficient and less maintenance. After all the old sirens have been removed and replaced ,SONGS sold 23 of the STL-10s to Curry County Oregon to be used as tsunami sirens, and the Model 120s and remaining 5 STL-10s are believed to have been scrapped ,but its unknown if they were ,or went somewhere else but hasn't been discovered. The only Model 120 that is remaining is in the possession of Aaron Allevato (Duderocks5539) and Edaan Friedman and currently under restoration to get back into operating condition.

Siren patent: https://patents.google.com/patent/US4649853