Southern California Edison Model 120: Difference between revisions

No edit summary |

ArxCyberwolf (talk | contribs) (Moved page over from the CDS Wiki.) |

||

| (26 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

{{Infobox siren | {{Infobox siren | ||

|image = | |image =Model 120.jpg | ||

|company= Southern California Edison | |company= Southern California Edison | ||

|produced= | |produced= 1982-1988 | ||

|type=[[Pneumatic]] | |type=[[Supercharged]] [[Electromechanical]] [[Omnidirectional]] [[Pneumatic]] | ||

|output=120 | |output=120 dB @ 100 ft | ||

|hertz = 240 or 300 | |hertz = 240 or 300 | ||

| | |caption=A Model 120 unit on a Sentry mount.|hp=2 hp (chopper) | ||

}} | 10 hp (blower)}} | ||

The | The '''Southern California Edison Model 120'''<ref>While Southern California Edison Model 120s are often referred to as "Toshiba" sirens by enthusiasts, these were not made by Toshiba. These were purely a custom-made design built in-house by Southern California Edison.</ref>, also known as the '''SoCal Edison Model 120''' or simply the '''Model 120''', is a 120 dB low tone supercharged electromechanical siren that was designed in-house by SONGS audio engineer John Glenn Powell specifically for use within the 10 Mile Emergency Planning Zone (EPZ) for the San Onofre Nuclear Generating Station (SONGS) during its operating life. It is one of a few examples of a siren that was purpose-built for a system. | ||

== History == | |||

Siren | [[File:Model 120 prototype being mounted to an existing STL-10 pole for range and output testing in 1982.jpeg|thumb|left|upright|Model 120 prototype being mounted to an existing [[Federal Signal STL-10|STL-10]] pole for range and output testing in Summer 1982.]]The Model 120 was created in 1982 as a custom-built siren for the SONGS plant, which had strict requirements for its siren system. SONGS had gone through two other systems before this point, with a system of 39 [[Sentry Siren|Sentry]] sirens originally being installed in August 1981 and tested in January 1982. The Sentry sirens were found to perform worse compared to what was advertised, leading to the sirens being removed. SONGS would then install a new system of 39 Federal Signal [[Federal Signal STL-10|STL-10s]], with those being installed by April of 1982 and tested in May of the same year. While the STL-10s performed significantly better than the Sentry sirens did, they still didn't meet the plant's needs, with insufficient coverage and a lack of corrosion resistance. | ||

The only sirens on the market at the time with enough range that would meet the plant's needs at the time were rotational, but SONGS wanted to use exclusively omnidirectional sirens to reduce maintenance costs. Some of [[Alerting Communicators of America|ACA's]] omnidirectional sirens, such as the [[ACA Cyclone|Cyclone]], were likely considered but did not meet the requirements either. With a lack of available options, SONGS opted to design and create their own siren to meet their requirements. The job of designing the siren was given to SONGS' audio engineer, John G. Powell, who created a compact, high-performance omnidirectional siren design using massive horns and a centrifugal blower. After being inspected by the plant, the siren was green-lit for production. Starting around June 1982, Model 120 prototypes started to be constructed and tested, with the final units being completed in March 1983. | |||

Originally, the plan was after the first Model 120s were installed, a total of 52 additional Model 120s were going to replace the existing Federal STL-10s and make the system entirely Model 120s. This plan was dropped shortly afterward due to the increasing delays and costs caused to the plant by not having a ready siren system by 1981 which was the original year planned for the plant's 2 newly constructed reactors to begin operating. Units #2 and #3 were ready to begin operation, but because the siren system was inadequate, they couldn't begin operation until the Model 120s were installed. This caused a delay for over a year, as it also happened around the same time the NRC required nuclear plants to have siren systems. This also meant the plant's existing Unit #1 could not be restarted until the siren system was ready. There were 22 of these sirens produced, with one being never installed and put into storage as a spare. | |||

16 of these were installed in October 1982 to add into the system of STL-10s, 8 of which indirectly swapped out with Model 120s with another 8 being brand new installs. 5 additional sirens were installed in 1988, one of which replaced a Federal Signal [[Federal Signal Thunderbolt|Thunderbolt]] that was an existing Civil Defense siren. After the Model 120s went up, to end the delays of the siren system not being up to par, SONGS opted to keep the remaining STL-10s and add 21 Model 120s in areas that need coverage to get the EPZ up to code for the plant's reactors to start. After a successful system test in July 1983, the plant's new reactors began operation shortly afterwards with Unit #2 starting on August 8th, 1983, and Unit #3 on April 1st, 1984, as well as Unit #1 being restarted. These delays and the cost of the sirens themselves cost the plant over $1,000,000. | |||

[[ | By June 2004, the plant began discussing a system replacement project due to the sirens suffering from advanced corrosion and degrading reliability due to the system's proximity to the ocean. A year later, beginning in November 2005 (a month after the annual siren test), the Model 120s and the STL-10s started to be gradually removed and replaced. By February 2006, all had been replaced by Whelen [[Whelen WPS-2800|WPS-2810]]<nowiki/>s and WPS-2806s that were installed in their places. The 2810s replaced the Model 120s and the 2806s replaced the STL-10s. These new electronic sirens had battery backup and voice capability (that was never used), were much lower maintenance due to their corrosion resistance, and had similar ranges to the sirens they replaced. These new sirens met the strict requirements of the plant without the need to specifically design a new siren. These would be later removed after SONGS was decommissioned. After all the old sirens had been replaced, SONGS sold 23 of the STL-10s to Curry County, Oregon, to be used as tsunami sirens, and the Model 120s and remaining 5 STL-10s were scrapped, save for a single Model 120 that was never installed, kept as a spare for parts and forgotten about. This last remaining unit is currently in private possession by Duderocks5539, undergoing restoration to eventually make it fully operational. | ||

== Design == | |||

The Model 120 is a unique mix of a supercharged and pneumatic electromechanical siren that lacks any vanes on the rotor, meaning it requires an external air source to produce any meaningful sound. The sound is created by a 4-port (later 5-port) single-tone rotor, which spins inside the stator and acts as a chamber to contain the air inside. The rotor is driven by a 2 hp TEFC AC motor that runs at 3450 rpm, driving the siren from above. The siren has an 8-port stator, and the sound is then projected by 8 large fiberglass horns attached to the stator. The siren makes use of a belt-driven Paxton centrifugal blower, that uses a 10 hp TEFC motor which sits below the siren's head to force pressurized air up into the rotor. This is a similar configuration to the Japanese [[Hankoku Electric Co., Ltd.|Hankoku]] siren, which also uses a centrifugal blower below the siren. | |||

The 4-port units reached a frequency of 240 Hz (480 Hz without the blower due to the lack of air resistance making the rotor spin faster) and the 5-port units reached 300 Hz, or 600 Hz without the blower. The rotor and stator are both coated in Teflon, which helps seal the air in and prevent leaks, while also helping to protect them from corrosion from the salty air. The Model 120 is massive in size, requiring a significant framework to hold up the siren's massive fiberglass horns, as well as the blower and the rotor/stator itself. The siren was designed for being mounted on poles rather than rooftops, attached to the pole either through a custom mount, or reusing the mounts from the Sentry sirens they replaced. | |||

== Gallery == | |||

<gallery mode="packed" heights="200px"> | |||

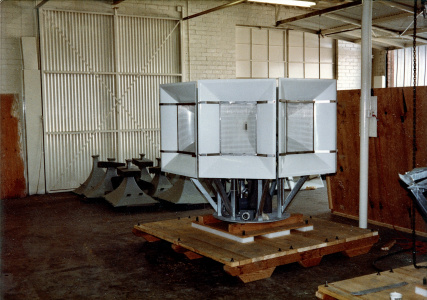

7 Model 120 heads and blowers.jpeg|7 Model 120 heads and blowers prior to being assembled. | |||

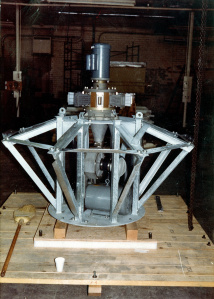

Assembled unit without horns.jpeg|Assembled unit without horns. | |||

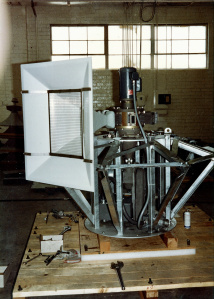

Horns being attached and conduits ran to main junction box.jpeg|Horns being attached and conduits ran to main junction box. | |||

5 out of the 8 horns attached with another unit being assembled off to the left.jpeg|5 out of the 8 horns attached with another unit being assembled off to the left. | |||

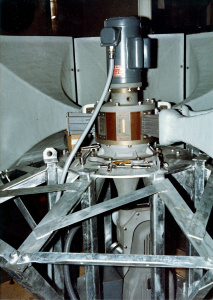

Closer view of the head with the siren 95% assembled.jpeg|Closer view of the head with the siren 95% assembled. | |||

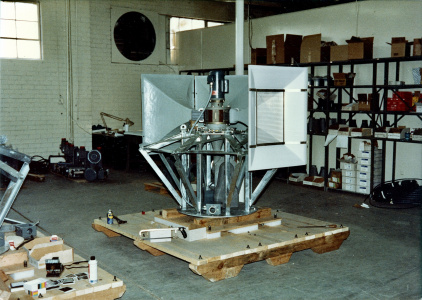

Fully assembled Model 120.jpeg|Fully assembled Model 120. | |||

Fully assembled Model 120 with the other 6 being assembled and crated up to be transported to San Onofre Nuclear Generating Station for installation in the 10 mile EPZ around May-June 1983.jpeg|Fully assembled Model 120 with the other 6 being assembled and crated up to be transported to San Onofre Nuclear Generating Station for installation in the 10 mile EPZ in October 1982. These were the first 7 to be installed which replaced 7 STL-10B's. | |||

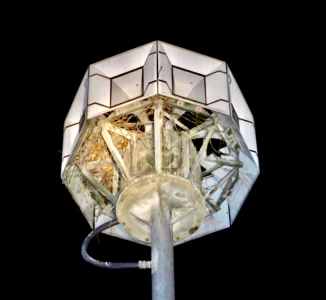

IMG 7890.jpeg|Siren Location SC-13 illuminated by a spot light at night in 2003. The siren was 21 years old at the time. | |||

99F6BBFC-E550-4A8C-8538-82E2356B663A.jpeg|Head of the privately owned unit with a salvaged motor attached. | |||

</gallery> | |||

== See Also == | |||

* Siren patent: https://patents.google.com/patent/US4649853 | |||

* Model 120 head run up: https://www.youtube.com/watch?v=mf7YC0Vc_ZI | |||

[[ | * Model 120 head dissembled: https://www.youtube.com/watch?v=yOcVk3SrqtY | ||

[[Category:Sirens]] | |||

[[ | [[Category:Omnidirectional Sirens]] | ||

[[Category:Electromechanical Sirens]] | |||

[[Category:Supercharged Sirens]][[Category:Single Toned Sirens]][[Category:SoCal Edison]] | |||

[[Category:Pneumatic Sirens]] | |||

__INDEX__ | |||

[[Category: | |||

Revision as of 20:49, 19 August 2024

| Southern California Edison Model 120 | |

A Model 120 unit on a Sentry mount. | |

| Company | Southern California Edison |

|---|---|

| Produced | 1982-1988 |

| Type | Supercharged Electromechanical Omnidirectional Pneumatic |

| Sound output | 120 dB @ 100 ft |

| Horsepower | 2 hp (chopper)

10 hp (blower) |

The Southern California Edison Model 120[1], also known as the SoCal Edison Model 120 or simply the Model 120, is a 120 dB low tone supercharged electromechanical siren that was designed in-house by SONGS audio engineer John Glenn Powell specifically for use within the 10 Mile Emergency Planning Zone (EPZ) for the San Onofre Nuclear Generating Station (SONGS) during its operating life. It is one of a few examples of a siren that was purpose-built for a system.

History

The Model 120 was created in 1982 as a custom-built siren for the SONGS plant, which had strict requirements for its siren system. SONGS had gone through two other systems before this point, with a system of 39 Sentry sirens originally being installed in August 1981 and tested in January 1982. The Sentry sirens were found to perform worse compared to what was advertised, leading to the sirens being removed. SONGS would then install a new system of 39 Federal Signal STL-10s, with those being installed by April of 1982 and tested in May of the same year. While the STL-10s performed significantly better than the Sentry sirens did, they still didn't meet the plant's needs, with insufficient coverage and a lack of corrosion resistance.

The only sirens on the market at the time with enough range that would meet the plant's needs at the time were rotational, but SONGS wanted to use exclusively omnidirectional sirens to reduce maintenance costs. Some of ACA's omnidirectional sirens, such as the Cyclone, were likely considered but did not meet the requirements either. With a lack of available options, SONGS opted to design and create their own siren to meet their requirements. The job of designing the siren was given to SONGS' audio engineer, John G. Powell, who created a compact, high-performance omnidirectional siren design using massive horns and a centrifugal blower. After being inspected by the plant, the siren was green-lit for production. Starting around June 1982, Model 120 prototypes started to be constructed and tested, with the final units being completed in March 1983.

Originally, the plan was after the first Model 120s were installed, a total of 52 additional Model 120s were going to replace the existing Federal STL-10s and make the system entirely Model 120s. This plan was dropped shortly afterward due to the increasing delays and costs caused to the plant by not having a ready siren system by 1981 which was the original year planned for the plant's 2 newly constructed reactors to begin operating. Units #2 and #3 were ready to begin operation, but because the siren system was inadequate, they couldn't begin operation until the Model 120s were installed. This caused a delay for over a year, as it also happened around the same time the NRC required nuclear plants to have siren systems. This also meant the plant's existing Unit #1 could not be restarted until the siren system was ready. There were 22 of these sirens produced, with one being never installed and put into storage as a spare.

16 of these were installed in October 1982 to add into the system of STL-10s, 8 of which indirectly swapped out with Model 120s with another 8 being brand new installs. 5 additional sirens were installed in 1988, one of which replaced a Federal Signal Thunderbolt that was an existing Civil Defense siren. After the Model 120s went up, to end the delays of the siren system not being up to par, SONGS opted to keep the remaining STL-10s and add 21 Model 120s in areas that need coverage to get the EPZ up to code for the plant's reactors to start. After a successful system test in July 1983, the plant's new reactors began operation shortly afterwards with Unit #2 starting on August 8th, 1983, and Unit #3 on April 1st, 1984, as well as Unit #1 being restarted. These delays and the cost of the sirens themselves cost the plant over $1,000,000.

By June 2004, the plant began discussing a system replacement project due to the sirens suffering from advanced corrosion and degrading reliability due to the system's proximity to the ocean. A year later, beginning in November 2005 (a month after the annual siren test), the Model 120s and the STL-10s started to be gradually removed and replaced. By February 2006, all had been replaced by Whelen WPS-2810s and WPS-2806s that were installed in their places. The 2810s replaced the Model 120s and the 2806s replaced the STL-10s. These new electronic sirens had battery backup and voice capability (that was never used), were much lower maintenance due to their corrosion resistance, and had similar ranges to the sirens they replaced. These new sirens met the strict requirements of the plant without the need to specifically design a new siren. These would be later removed after SONGS was decommissioned. After all the old sirens had been replaced, SONGS sold 23 of the STL-10s to Curry County, Oregon, to be used as tsunami sirens, and the Model 120s and remaining 5 STL-10s were scrapped, save for a single Model 120 that was never installed, kept as a spare for parts and forgotten about. This last remaining unit is currently in private possession by Duderocks5539, undergoing restoration to eventually make it fully operational.

Design

The Model 120 is a unique mix of a supercharged and pneumatic electromechanical siren that lacks any vanes on the rotor, meaning it requires an external air source to produce any meaningful sound. The sound is created by a 4-port (later 5-port) single-tone rotor, which spins inside the stator and acts as a chamber to contain the air inside. The rotor is driven by a 2 hp TEFC AC motor that runs at 3450 rpm, driving the siren from above. The siren has an 8-port stator, and the sound is then projected by 8 large fiberglass horns attached to the stator. The siren makes use of a belt-driven Paxton centrifugal blower, that uses a 10 hp TEFC motor which sits below the siren's head to force pressurized air up into the rotor. This is a similar configuration to the Japanese Hankoku siren, which also uses a centrifugal blower below the siren.

The 4-port units reached a frequency of 240 Hz (480 Hz without the blower due to the lack of air resistance making the rotor spin faster) and the 5-port units reached 300 Hz, or 600 Hz without the blower. The rotor and stator are both coated in Teflon, which helps seal the air in and prevent leaks, while also helping to protect them from corrosion from the salty air. The Model 120 is massive in size, requiring a significant framework to hold up the siren's massive fiberglass horns, as well as the blower and the rotor/stator itself. The siren was designed for being mounted on poles rather than rooftops, attached to the pole either through a custom mount, or reusing the mounts from the Sentry sirens they replaced.

Gallery

-

7 Model 120 heads and blowers prior to being assembled.

-

Assembled unit without horns.

-

Horns being attached and conduits ran to main junction box.

-

5 out of the 8 horns attached with another unit being assembled off to the left.

-

Closer view of the head with the siren 95% assembled.

-

Fully assembled Model 120.

-

Fully assembled Model 120 with the other 6 being assembled and crated up to be transported to San Onofre Nuclear Generating Station for installation in the 10 mile EPZ in October 1982. These were the first 7 to be installed which replaced 7 STL-10B's.

-

Siren Location SC-13 illuminated by a spot light at night in 2003. The siren was 21 years old at the time.

-

Head of the privately owned unit with a salvaged motor attached.

See Also

- Siren patent: https://patents.google.com/patent/US4649853

- Model 120 head run up: https://www.youtube.com/watch?v=mf7YC0Vc_ZI

- Model 120 head dissembled: https://www.youtube.com/watch?v=yOcVk3SrqtY

- ↑ While Southern California Edison Model 120s are often referred to as "Toshiba" sirens by enthusiasts, these were not made by Toshiba. These were purely a custom-made design built in-house by Southern California Edison.